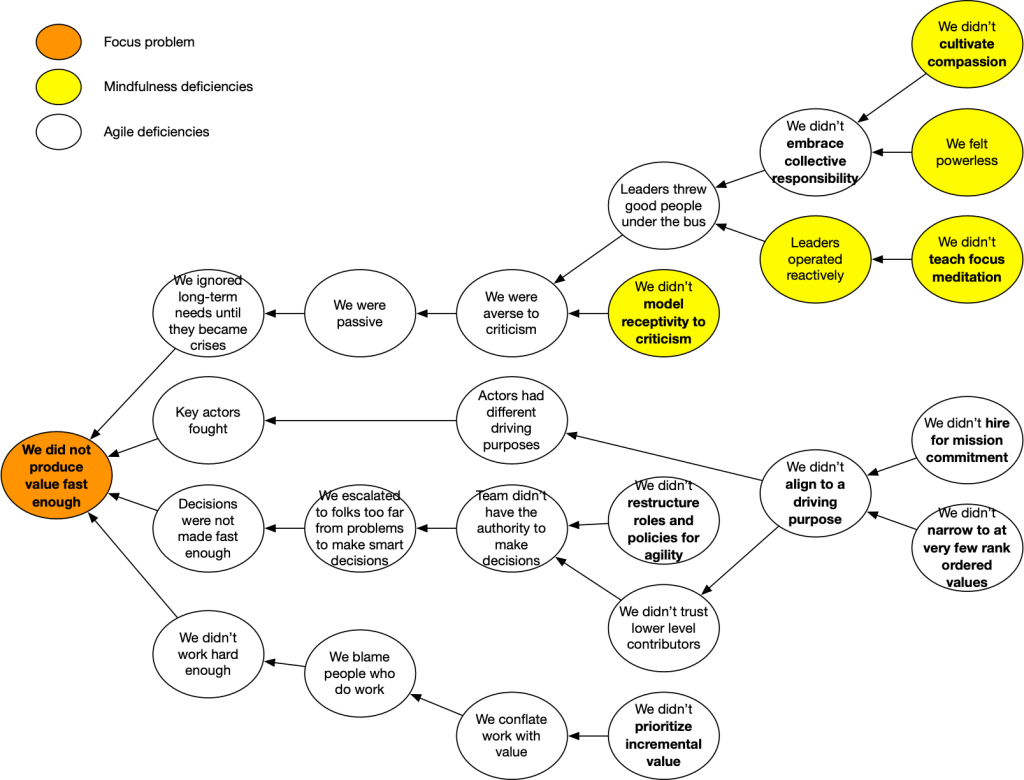

Agile transformation efforts address one focus problem: We did not produce value fast enough. The Agile Five Whys graph helps advocates identify dysfunctions more rapidly and introduce the most productive practices first.

This paper demonstrates the Agile Five Whys graph on a subset of dysfunctions, and suggests mitigation practices for faster value production. By reminding us of common dysfunctions and their root causes, the Agile Five Whys graph can provide easier diagnosis and improvement in organizational, team, and individual behavior.

To create an agile five whys graph, start with the focus problem: We did not produce value fast enough, and then ask Why? Initially, you are likely to get some obvious first-level causes. But then ask Why? with each first-level cause to get second-level causes. You can continue asking Why? like a 4 year-old child might. At Toyota, employees are told that they must identify at least some fifth-level causes before they conclude that they understand the causes sufficiently to recommend a solution. The graph above went further than five to identify some sixth-level causes.

Some nodes assert “We didn’t <do something>”. Those nodes refer to fundamental practices from the Agile Canon (Greening 2016). So the Agile Five Whys tool can prescribe specific agile coaching. For the past decade, I’ve been cataloging fundamental practices in a project called The Agile Canon. The more complete Agile Five Whys graph, under development, lists all existing practices in the Agile Canon. This graph subset references two practices documented in the Agile Canon: Embrace Collective Responsibility and Align to a Driving Purpose.

Some fundamental practice nodes appear in this graph, but are not yet documented. Thus the Five Whys approach is identifying areas for my (or your) further development. See the Call to Action section for how you might help.

Exploring Five Whys

Most people unfamiliar with Five Whys stop inquiring about causes at the first level. If they bother to consider more than one first-level cause, they typically identify the most prominent cause (or the safest cause, if they want to avoid blame), and take immediate action. This is mindless reactivity at work, sometimes called “intuition.”

What might the mindless do, when faced with the problem We did not produce value fast enough? The graph above offers some mindless possibilities:

- If We ignored long-term needs until they became crises, the mindless might tell people to think more deeply (“Wake up people!”), create a committee (“Say it together!”), or hire a consultant (“Fresh, ignorant eyes can help us!”).

- If Key actors fought, the mindless might fire one or more of the culprits.

- If Decisions were not made fast enough, the mindless might decide they need more executives to be available to make time-critical decisions.

- If We didn’t work hard enough, the mindless might tell people to work harder. Supervisor over-attribution and subsequent abusiveness is typical (Lyubykh 2021)

Examining the graph reveals that hidden, systemic causes (at deeper levels) may remain after a first-level cause is mitigated, with little sustainable improvement on the focus problem.

Let’s follow one of the chains to demonstrate finding deeper causes. The superficial first-level cause We didn’t work hard enough is where many executives stop. They assume employees were goofing off, didn’t have enough motivation, or had a side job. If they were mindful executives, they might explicitly place those hypothesized causes on the graph, and then determine Is it true? If they were true, then employers could supervise more closely, provide performance bonuses, or prohibit moonlighting in contracts. But, in most cases, these hypothesized causes are not real.

Instead, we often discover that We blamed people who do work. There’s a problem, there’s a person associated with the problem, therefore the person must be to blame. There’s a funny phrase that illustrates this problem: “No good deed goes unpunished.” Mindless managers usually advocate reactive solutions. And those reactive solutions could mean firing good employees. Punishing or severing good employees not only reduces our average productivity, but erases institutional knowledge.

If we ask why we blamed people who do work, usually we assumed guilt-by-association and failed to examine the problem deeply enough. One obvious mitigation is to use five whys to explore dysfunctions. In doing so, we expose our hypotheses, invite verification, and generate more thoughtful hypotheses.

Another cause of agile dysfunctions is We conflated work with value. This dysfunction is so commonplace that a whole form of project management, called Earned Value Management, arose to gauge progress in government contracts. “EVM is a project management methodology that integrates schedule, costs, and scope to measure project performance.” Nowhere in this phrase do we see direct assessment of value. EVM derives the value of a partially completed project by multiplying the speculative value assigned by a contracting agency by the fraction of the project completed. And therefore EVM conflates work with value. The mitigation for this is to analyze value independently of the work invested, ideally by getting feedback from stakeholders who should benefit from the work.

The most important agile mitigation for conflating work with value is to optimize incremental value. This is a complex topic—involving ranked backlogs, story splitting, risk analysis, real options, cost of delay analysis—all in service of frequent delivery, value measurement, and adaptation.

This four-whys-long chain generated deep insight. We can produce value faster by using five whys to explore dysfunctions and optimize incremental value. Superficial analysis and reactive decision making, used by many managers, usually make things worse.

Agile and Mindfulness Dysfunctions

My research has long been in agile dysfunctions and practices, I am now exploring mindfulness dysfunctions and practices. While most causes we see here are classic agile dysfunctions found in many organizations (where classic agile practices provide solutions), some causes are better characterized as mindfulness dysfunctions (where mindfulness practices provide solutions). I have color coded the graph above with agile dysfunctions in white nodes, mindfulness dysfunctions in yellow nodes, and the focus problem in an orange node.

What constitutes an agile dysfunction? Typical agile practices explore and address communication and process causes, with short-cycle experimentation (sprints or iterations). The short cycles expose causes that delay feedback, learning and adaptation. Examples of such causes include repetitive “overhead,” such as testing, integration, deployment, inter-team communication. But in “mindless” organizations, the stresses caused by agile practices can lead to reactivity and sometimes in rejection of agile practices, despite data showing dramatically faster value production.

So then, what constitutes a mindfulness dysfunction, which we’ve called “mindless” throughout this post? They are reactive actions—often termed “intuitive,” “gut reaction,” or “common sense”—which are cognitively biased, ignorant of dependencies, short-term selfish (as opposed to “enlightened self-interest,” which is often mindful). Mindfulness practices explore and mitigate these dysfunctions with various forms of meditation, contemplation, and analysis. For example, the “Five Whys” approach discussed here (a form of dependency analysis) was developed at Toyota, where practices likely were drawn from the culturally prevalent Soto Zen Buddhist philosophy (Chiarini 2018).

Summary

The focus problem of all agile efforts we’re aware of is “We did not produce value fast enough.” Five Whys is a technique that can help us identify dysfunctions in organizational, team, and personal behavior, and can recommend agile and mindfulness practices that can mitigate those dysfunctions.

The Five Whys subset we discuss here illustrates how dysfunctions motivate practices, and shows some practices that need documentation. We also mention how some mindfulness practices mitigate dysfunctions, opening up a new area of exploration for business, team, and individual agility.

Call to Action

Do you want to be more calm and effective in your work or life? Sign up for our newsletter with the Subscribe form on this page.

Credits

These people, so far, helped with this project: Jeff McKenna, Dahm Hongchai, Erik Gibson.

References

Chiarini A, Baccarani C, Mascherpa V (2018) Lean production, Toyota Production System and Kaizen philosophy: A conceptual analysis from the perspective of Zen Buddhism. The TQM Journal 30.

Greening DR (2016) Agile Base Patterns in the Agile Canon. 2016 49th Hawaii International Conference on System Sciences (HICSS). (IEEE, Koloa, HI, USA), 5368–5377.

Lyubykh Z, Bozeman J, Hershcovis MS, Turner N, Shan JV (2021) Employee performance and abusive supervision: The role of supervisor over‐attributions. J Organ Behavior 43(1):125–145.

Leave a Reply